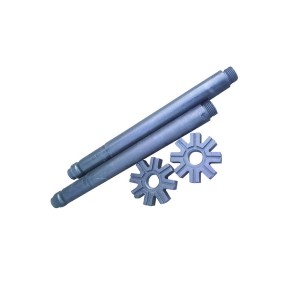

Tsarin Rotor

Tsarin Rotor

An yi amfani da na'ura mai juzuwar hoto da mai zafin hoto daga babban hoto mai tsabta. An yi amfani da farfajiyar tare da maganin hana-shaƙuwa na musamman, kuma rayuwar sabis kusan sau 3 ne na na samfuran yau da kullun. An yadu amfani a aluminum gami da simintin masana'antu.

Tsarin tsarkakewa na gami na aluminium shine babbar hanyar don inganta ingantaccen aikin gami na aluminum. A cikin aikin tsarkakewa, hanyar hada gas din tsarkakewa da narkewar sinadarin da fesa rotor graphite zuwa narkewar alminiyon shine mafi ingancin hanyar magani a duniya. Tsarin aiki na rotor graphite shine: rotor mai juyawa ya karya nitrogen (ko argon) da aka busa cikin narkewar aluminium zuwa yawan kumfar da aka tarwatsa ya watsa su cikin narkakken karfe. Bubbles a cikin narkar da dogaro da bambancin matsin lamba na gas da kuma ka’idar tallata farfajiyar don sha ruwan hydrogen a cikin narkewar, adsorb oxidized slag, kuma a fitar dashi daga narkar da farfajiyar yayin da kumfa ke tashi, don a sami damar tsarkake narkewar. Saboda kumfa kanana ne kuma sun tarwatse, ana hade su daidai da narkewar da ke juyawa, sannan kuma suna juyawa cikin sihiri karkace don yin iyo a hankali. Lokacin tuntuɓar tare da narkewar yayi tsawo, kuma ba za a ƙirƙira iska da iska ke samarwa ta ci gaba da hauhawar layi ba, don haka cire hydrogen mai cutarwa a cikin narkewar aluminum. Ingantaccen aikin tsarkakewa.

Don kayan haɗin gwal na aluminum da masana'antun samfuran aluminum, yana da matukar mahimmanci don rage farashin sarrafawa. Dangane da wannan, rotors rotor wanda kamfaninmu ke samarwa na iya kawo fa'idodi masu zuwa. 1. Rage kudin sarrafawa 2. Rage yawan amfani da iskar gas mai aiki 3. Rage abun ciki na aluminium a cikin slag 4. Rage farashin kwadago 5. Inganta aiki, zagayen maye mai tsawo 6. Inganta aminci da rage farashin kulawa.

Saboda bayanai dalla-dalla na rotors wanda aka yi amfani da su a kowane layin samar da simintin gyare-gyare ba iri daya bane. Na farko, abokin ciniki yana ba da zane-zane na asali kuma ya cika cikakke a cikin filin rotor mai amfani da hanyar binciken muhalli. Bayan haka, bisa ga zane-zane, haɗe tare da saurin rotor na hoto, shugabanci na juyawa da matsayin danginsa zuwa matakin ruwa na alminiyon, ana gudanar da bincike na fasaha, kuma ana ba da jituwa ta hana lalatawa. Shirin magani na Oxidation.

An sanya bututun mai juya hoto wanda aka zana daga hoto mai tsayi. Baya ga yin la'akari da buƙatar fasa kumfa, tsarin bututun yana amfani da ƙarfin centrifugal da aka samar ta hanyar zuga narkewar gami na alumini don yin narke ya shiga cikin maƙarƙashiyar kuma a haɗe tare da iskar gas da aka fitar a kwance don samar da gas / Jirgin ruwa an fesa shi don ƙara yankin tuntuɓar da lokacin tuntuɓar kumfa da ruwan gami na aluminium, da inganta tasirin tsarkakewar degassing.

Za'a iya daidaita saurin rotor graphite ta hanzarin sarrafa saurin saurin mitar, har zuwa 700r / min. Bayani dalla-dalla na rotor rotor Φ70mm ~ 250mm, kuma bayanin impeller shine Φ85mm ~ 350mm. Babban-iska-hadawan abu da iskar shaka graphite na'ura mai juyi yana da halaye na babban ƙarfi, high zazzabi juriya, kuma aluminum ya kwarara lalata juriya. A yayin tsarkakewa da gurɓatawa, saman ruwan gami na aluminium a cikin akwatin an lulluɓe shi da nitrogen don kariya, don haka ɓangaren daga cikin rotor graphite da aka fallasa daga ruwan gishirin na aluminium yana cikin iskar gas mai aiki don hana haɓakar zafin jiki mai yawan na'ura mai juyi da tsawaita rayuwar mai amfani da rotor.

An fasalta fasalin impeller, wanda zai iya rage juriya yayin juyawa, kuma ƙwanƙwasawa da ƙwanƙwasawa tsakanin impeller da ruwan gami na alminium ƙananan ƙananan. Don haka ƙimar degassing tana sama da 50%, taƙaita lokacin narkewa da rage farashin samarwa.